DCC DECODER TYPES

Even though DCC decoders are made in a seemingly infinite number of styles they can virtually all be classified into one of three different types: ‚Äúwired‚ÄĚ, ‚Äúdrop-in‚ÄĚ or ‚Äúplug and play‚ÄĚ. Wired (or hard-wired)decoders are undeniably the most versatile as they can be installed in any locomotive that they can physically be fitted into as long as their current rating will safely supply the motor's requirements. Be careful if you plan to install a Z or N scale decoder in an HO engine. Many modelers believe that if a decoder must be installed wire by wire it must be the most difficult to install. Maybe and maybe not. Life-Like Proto 1000 engines, for example, have a circuit board at the top of the mechanism with X's marked at three different locations where traces are cut for DCC operation and the decoder wires are then soldered onto pre-marked, labeled pads; Presto! Your decoder is installed! But this is an unusual example. On older engines especially, care must be taken to locate the different contact points to solder the decoder wires to, and to make sure motor brushes are isolated. Careful inspection and sometimes modification must be carried out.

A second type of decoder is the so-called "drop-in" style. These decoders are made for locomotives that come equipped with some sort of circuit board or light board installed. The factory board is removed after the attached wires are gently detached, and the decoder is installed to take its place. Size and shape of the decoder matches the original board, and wire connection points are located in the same relative position. Wire connections are often accomplished by means of small plastic "boots" or retainers, although most decoder manufacturers recommend soldering the connections for better, more lasting reliability. This process is usually fairly simple, however some light boards, as in the very popular Kato products first offered by companies such as Atlas, can be a little tricky to disassemble from the loco. This can make the term "drop-in" a little misleading.

The last decoder type, the "plug and play" style, is probably the easiest to install in most instances. They usually use an NMRA medium plug with eight pins for electrical contact. The plug is simply inserted into a socket built into the locomotive or steam loco's tender. Then, if everything has been correctly wired at the factory, you are ready to program and have at it. Some plug n' play decoders have the plug at the end of a wire harness and others have an integral plug that is part of a circuit board just like a drop-in decoder. One word of caution: This is not an essay on decoder installation but it should be mentioned that all decoder manufacturers strongly recommend that new decoders be tested before installation as well as the socket that plug n' play decoders are plugged into. Most companies (with one exception) will not warranty a decoder that has been "installed first and tested later.

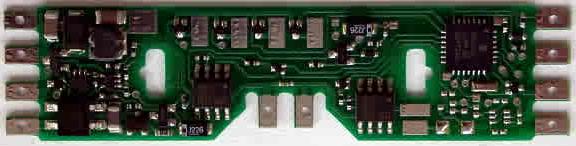

Below from left to right: Wired - Drop-In - Plug and Play